UPVC Pipe System !

An accurately recommended (Un-plasticized Polyvinyl Chloride) UPVC pipe system is the most desirable hunt in all forms of quality constructions, water supply schemes and waste discharge projects due its magnificently remarkable properties that not only make it lesser health hazardous and long lasting but more importantly make it economical comparing with old conventional pipe systems.

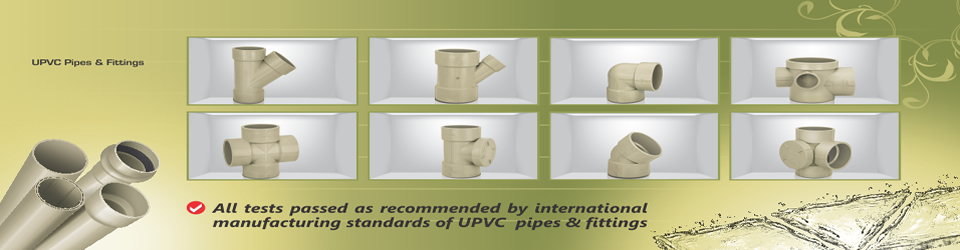

Master UPVC piping system is the best available piping systems in the country for its uncompromised supreme quality, attained by stringent adherence to the international manufacturing standards.

Introduction

The One & Only in Pakistan by their standards and price range!

The importance of your water networks in your home is similar to the blood circulation system in our body. One blockage or rupture can result in partial or complete dysfunction of the body (Paralysis) or can even be fatal. Cement pipes have an average life of 10 years while substandard UPVC pipes and fittings are the most expensive bet as they don’t have a defined life. They might cheat and ruin the home of your dreams any moment.

So when you choose UPVC for the water networks of your dream home, don't compromise on international standards just for saving a few bucks. This saving for the time being will cost you a lot of money as well as mental torture and effort in the long run.

Master UPVC Pipes and Fittings are the first in Pakistan to strictly comply with all the international standards. As a result, we are the one and only product around with a life of 50 to 100 years subject to standard laying / installation / application procedures. The state of the art manufacturing and testing processes with us assure it and that’s how we are in a position to guarantee it.

Yes! We are expensive Because:

We use pure & virgin raw materials, which are verifiable. Ours is the only product in the market with 100% wall thickness as per Schedule/International Standard whereas others claim compliance but wall thickness is much below the standard.

International standards recommend addition of a filler, "Calcium Powder", in a small percentage to which our products strictly adhere. Others in the market are adding much higher quantities to save the cost while weakening the product to a dangerous level.

In the end result, we are giving you the ultimate value in the right price. We are investing more into the product to make your dream buildings safe and trouble free for a lifetime. We are compromising on nominal profit to give you a product that is second to none. Others in the market are saving money at each and every step of production making the product a high risk for your building while giving bigger profits to such cheating monsters.

Technical Specification UPVC

Vigorous testing on every stage from raw materials to the finished product is carried out in our state of the art lab only one of its kind in Pakistan. Our latest hi-tech manufacturing facility, unmatched in Pakistan, allows us to meet the following global standards in our products:

- UPVC Pipes as per American Standard, ASTM – D/1785 (Schedule – 40 and Schedule – 80) & D/2241 (SDR Series)

- UPVC Fittings as per American Standard, ASTM D/2466 (Schedule – 40)

- UPVC Pressure Pipes as per British Standard BS 3505 (PS 3051)

- High Precision moulding on computerized injection moulding machine

- State of the art imported pipe extruding plants

- Capacity & Capability of producing pipes on any given International Standard

Features

Promising lifetime 'peace of mind' right from purchase

- Zero maintenance cost on recommended installation; hassle free life long service

- Light weight, easy to handle and install; making the system cost effective

- Resistant to almost all types of chemical or electrochemical corrosions

- Hygienically suitable for drinking water pipe distribution systems, both main and supply lines

- Long life reliability for sewer and discharge pipe systems

- Resistant to various aggressive chemicals (Acids, Salts and Alkalis)

- Designed for easy installation with ultimate joint reliability for zero leakage

Standard Quality Assurance Procedures

Every batch has to go through the following Quality Tests as per our standard Quality Assurance Scheme in our in-house hi-tech testing labs:

- Specific Gravity Test

- Filler Test

- Opacity Test

- Glycerin Test

- Heat Reversion Test

- De-lamination Test

- Dichloromethane / Methylene Chloride Test

- Impact ResistanceTest

- Hydro Static Pressure Test

- Yield Strength Test

- Compression Test

- Dimensional Tests (Ovality, Outer Diameter, Inner Diameter and Wall Thickness)

- Visual Appearance Tests (Surface finish, [Scratches, Holes, Presence of Foreign Particles, Lines on surface and any other visual manufacturing /process flaws], Thickness Variation.